BANGLADESH SHIPS SUCCESS

Thriving hub for global freight, trade, and shipping logistics.

MORE INFORMATION

BANGLADESH

Overview:

In 2022, Bangladesh was the number 34 economy in the world in terms of GDP (current US$), the number 52 in total exports, the number 47 in total imports, the number 136 economy in terms of GDP per capita (current US$) and the number 101 most complex economy according to the Economic Complexity Index (ECI).

Exports:

The top exports of Bangladesh are Knit T-shirts ($9.06B), Non-Knit Men’s Suits ($8.82B), Knit Sweaters ($8.02B), Non-Knit Women’s Suits ($6.63B), and Knit Women’s Suits ($4.08B), exporting mostly to United States ($11.7B), Germany ($10.2B), United Kingdom ($4.86B), Spain ($4.41B), and Poland ($3.53B).

In 2022, Bangladesh was the world’s biggest exporter of Non-Knit Men’s Shirts ($2.59B), Knit Men’s Shirts ($1.44B), Jute Yarn ($528M), Jute and Other Textile Fibers ($205M), and Textile Scraps ($171M).

Imports:

The top imports of Bangladesh are Refined Petroleum ($11.3B), Raw Cotton ($2.9B), Non-Retail Pure Cotton Yarn ($1.97B), Scrap Iron ($1.86B), and Palm Oil ($1.77B), importing mostly from China ($26.8B), India ($13.8B), Singapore ($4.68B), Malaysia ($4.23B), and Indonesia ($3.89B).

In 2022, Bangladesh was the world’s biggest importer of Heavy Pure Woven Cotton ($1.42B), Heavy Mixed Woven Cotton ($1.03B), Light Pure Woven Cotton ($975M), Flax Woven Fabric ($381M), and Woven Fabric of Synthetic Staple Fibers ($318M).

Location:

Bangladesh borders Burma and India by land.

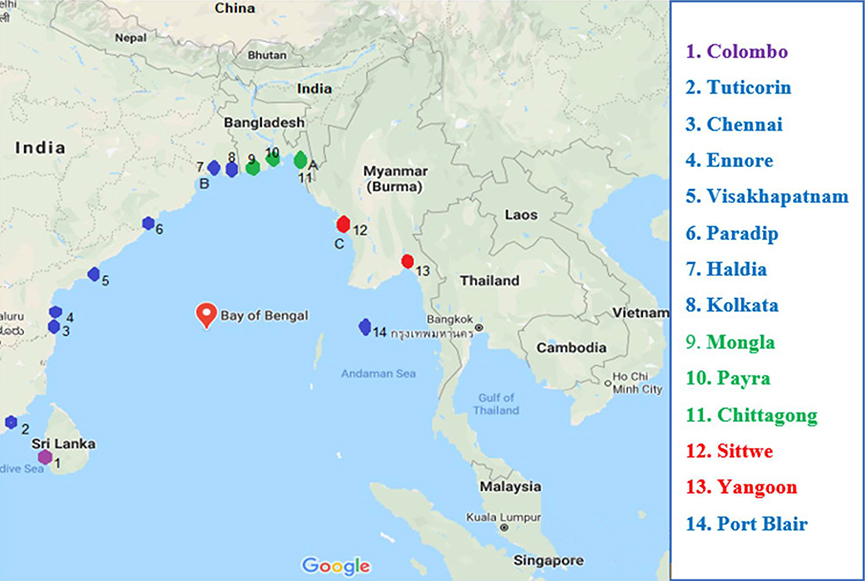

Bangladesh Map with Port Indication

Green garments factories: Bangladesh is a global champion

The recognition of green performance in the garment industry opens the doors to future investments, propelling the nation towards a sustainable future.

The world’s highest-rated LEED-certified green Garment factory. The facility boasts a host of green measures, including a rainwater harvesting system.

About 60 workers on one of the factory floors are busy making export-quality frocks as they hurriedly finish their work ahead of lunch. Despite the summer heat outside, only a few ceiling fans are switched on and the factory floor is quite cool.

Although there is not a single air cooler, the atmosphere inside the factory – which scored 106 out of 110 points in the United States Green Building Council’s (USGBC) Leadership in Energy and Environmental Design (LEED) rating system – remains comfortable.

Being a small unit that employs just 900 workers, it has been using green technologies to make the factory floor welcoming.

The factory land has left 35 percent of the space open and planted trees to facilitate the free flow of fresh air inside and outside the factory. The ceiling is five feet higher than in normal buildings, so rooms are not easily warmed by the summer heat. It also reduces humidity.

Green garment factories use electricity produced from their solar panels that bring down the consumption of fossil fuel-generated power.

Several exhaust fans have been installed to suck out warm air and draw in fresh air. Therefore, only a few electric fans are adequate to cool the room. The open space inside the factory harvests rainwater during the rainy days to use as an alternative to groundwater.

The factory uses 45 kilowatts of electricity produced every day from its solar panel which lessens the use of fossil fuel-generated power. The total requirement of electricity for the unit is 225 kilowatts daily.

The USGBC has four categories for green building: platinum, gold, silver and green. Bangladesh, which has demonstrated exceptional dedication to eco-friendly practices, now has 213 LEED-certified factories, with 80 platinum and 119 gold-rated factories. Currently, Bangladesh is home to 54 of the top 100 LEED-certified factories globally, including nine out of the top 10, and 18 out of the top 20 units. Additionally, the country boasts the two highest-rated LEED-certified factories.